August 8 2006 Authority. Pressurized hydraulic oil is used in cylinders which are tubes containing rams.

Setting Up A Tank For Contamination Control And Oil Analysis

Full PDF Package Download Full PDF Package.

. Large actuators can exceed 10000 psi. It makes sure that the fluid flowing through the hydraulic system is free of contamination enabling continuous operations. Water age can be managed through a well-designed system that exercises the tank.

Though any storage tank for fuel may be so called the term is typically applied to part of an engine system in which the fuel is stored and propelled or released pressurized gas into an engineFuel tanks range in size and complexity from the small plastic tank of a butane lighter to the multi. HANDBOOK OF HYDRAULIC FLUID TECHNOLOGY. L is length of pipe feet D is diameter of pipe square feet V is mean velocity fps C h is Hazen-Williams friction coefficient.

Pressures used in a hydraulic actuator ranges between 1000 to 5000 pounds per square inch psi. A trailer with different compartment can transport different kinds of liquid at the same timeThis reduces the transportation cost and saves fuel because the trips are reduced to one. Thus noise has become an important issue in aricraft design.

The tank is a storage unit. 29 MAR 16 Department of Environment and Science The Manual does not detail operational standards for regulated structures. 21 Full PDFs related to this paper.

The vessels are automatically recharged by a small engine-driven hydraulic pump with an integral pressure relief valve. Safety of operation 2. Download Full PDF Package.

STORAGE TANK DESIGN AND CONSTRUCTION GUIDELINES rev. A nacelle n ə ˈ s ɛ l nə-SEL is a streamlined body sized according to what it contains such as an engine fuel or equipment on an aircraftWhen attached by a pylon entirely outside the airframe it is sometimes called a pod in which case it is attached with a pylon or strut and the engine is known as a podded engineIn some casesfor instance in the typical Farman type. How high does the.

Regardless of its function and design every hydraulic system has a minimum number of basic components in addition to a means through which the fluid is transmitted. A fuel tank also called a petrol tank or gas tank is a safe container for flammable fluids. ISO 102621998 Earth-moving machinery - Hydraulic excavators - Laboratory tests and performance requirements for operator protective guards.

DESIGN CONSIDERATIONS 31 General - In unsewered areas every house should have arrange- ments for its sewage being treated in a septic tank effluent from which should be given secondary treatment either in a biolo anaerobic filter on the land or in a sub-surface disposa f ical filter upflow system. A short summary of this paper. Quieter operation is also important during midflight for passenger comfort.

Considerations include water turn-. A look at hydraulic power pack design and operation. Which One to Choose The technology of all three of these systems is well developed.

The design phase of a new tank project is the best time to consider how a tank design and piping configuration may contribute to water quality. To better understand the operating principles and design features in a hydraulic power unit it may be helpful to look at the basic components of a standard model used in industrial hydraulic systems. G609 is an alternate to ISO 3449 Level I and ISO 10262 Level I FOPS as a method of compliance.

Table 1 - Source. When analyzing or designing a hydraulic circuit the following three important considerations must be taken into account. So tank pressure must be taken into consideration during design.

HYDRAULIC CIRCUIT DESIGN AND ANALYSIS A Hydraulic circuit is a group of components such as pumps actuators and control valves so arranged that they will perform a useful task. How far does the lift station need to pump. The next steps in design are site considerations.

Clean hydraulic fluids and mining equipment are one of the most important considerations in this case. 1 Basic Hydraulic Systems. WCB G609 Standard - Mobile Equipment Roof Structures -- Light Duty.

Manual Manual for assessing consequence categories and hydraulic performance of structures Page 4 of 34 ESR20161933 Version 502 Effective. Hydraulic actuators use pressurized fluid energy to drive the ram and operate the device or machine that the actuator serves. Hydraulic Design Handbook by Mays The conventional form of the equation has been re.

Section 19-13-B102d2 of the Regulations of Connecticut State Agencies RCSA requires approval from the Department of storage tanks prior to construction. Hydraulic Starting Systems Hydraulic systems use hydraulic oil stored in steel pressure vessels under high pressure. The discharge could be in a pressurized holding tank.

N Energy dissipated due to friction and turbulence during pump operation Major Losses Friction Losses Due to friction between pumped water and inner surface of piping H f 302 L D-1167 VC h185 Hazen-Williams Formula where. Transporting each liquid in a different tanker is more expensive and inefficient. Hydraulic filter element is a key product that you can easily use in cleaning the hydraulic fluids in the system.

51006 1 of 10 Water Works Design and Construction Effective Date. Water circulation and water flow should be included in the design parameters. And pumping strength are also significant considerations.

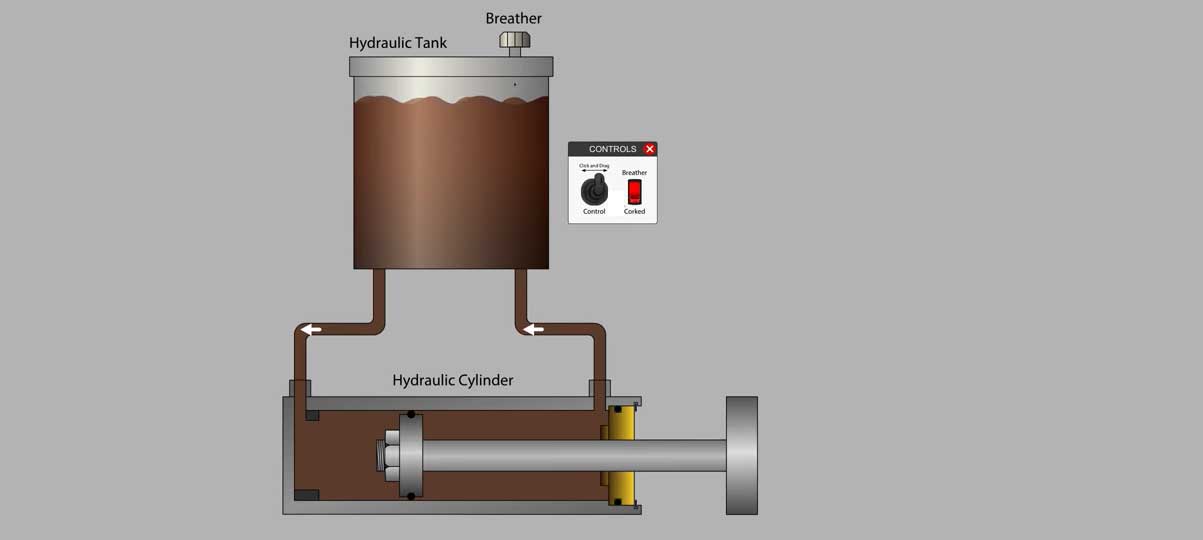

Hydraulic Reservoir Design Considerations

Practice Good Hydraulic System Maintenance

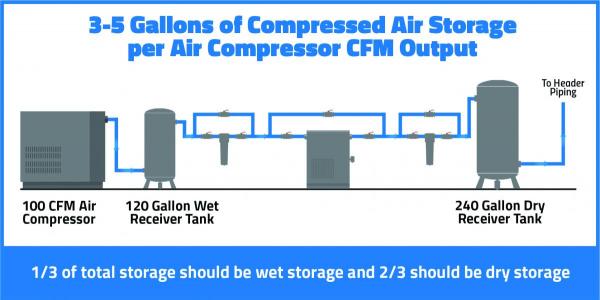

Air Receiver Tank Care Guide Sizing Safety And Storage Part 2 Compressed Air Best Practices

The Use Of Frp Materials And Components To Impede Or Repair Corrosion In Infrastructure Applications Continues To Mak Glass Suppliers Corrosion Water Pipes

Hydraulic Reservoir Design Considerations

Troubleshooting Hydraulic Reservoirs Breathers And Filters

Different Types Of Cracks In Beam Civil Engineering Handbook Civil Engineering Civil Engineering Construction

0 comments

Post a Comment